In commencing this stage a meeting was held to discuss everyones thoughts on how they felt the measure stage went. It was interesting because as there was a project being undertaken on how to improve the cleaning process all the operators began to observe faults in the cleaning procedure. It was that they have been in this same routine for the past number of years and no one has took a step back and to observe the cracks in the cleaning procedure. It was a rewarding meeting as it is felt that all compression operators not just team members are committed to this project as it will benefit all involved.

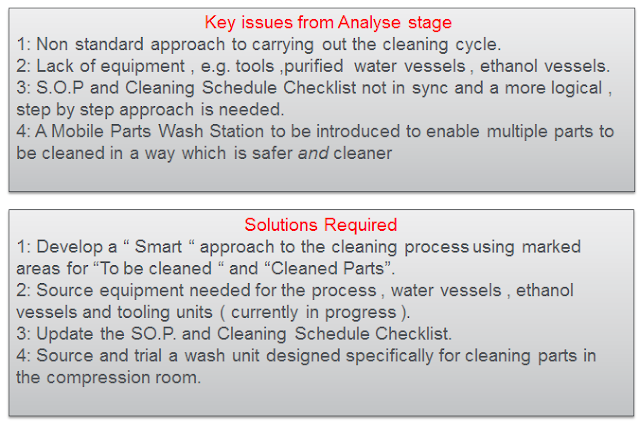

With the observations made throughout the measure stage and input from the meeting a fish bone diagram was developed.

This was a useful tool in identifying possible causes to the erratic cleaning procedures, it captures the links and relationships among the potential causes and results displayed in the diagram.

Throughout this project so far I have found brainstorming very effective. It has been efficient tool in acquiring some very useful information.

During brainstorming sessions the 5 whys worksheet was developed. According to Eric Ries "Behind every seemingly technical problems, is a human problem waiting to be found." We can relate to this in many ways in this project. The cleaning S.O.P has not been updated for 10 years, in those 10 years new tools and equipment is being used which can greatly improve the cleaning and quality conditions in the operational room.

The pace chart analysis was used to indicate the areas for the team to prioritise. Its a great tool to save time and resources. It helps to keep the team focused on the main goals of the project we hope to achieve.